- Problem communicating with modbus poll slave serial#

- Problem communicating with modbus poll slave drivers#

- Problem communicating with modbus poll slave software#

- Problem communicating with modbus poll slave code#

- Problem communicating with modbus poll slave Pc#

‘from 1 s to several seconds at 9600 bps’.

Problem communicating with modbus poll slave serial#

The Modbus over Serial Line Specification & Implementation Guide V1.0 document from recommends much longer than this i.e. As a rule of thumb, many Modbus masters use a one second slave reply timeout to accommodate the slowest responding device on the bus since failing to allow enough time for a device to respond can result in bus contention. Just be sure to wait at least 0.5 seconds before timing out on the reply (Note: On WattNode firmware version 16 or later, the reply timeout can be as short as 25 milliseconds). With many Modbus slaves you also need to be careful not to poll the slaves too quickly but the WattNode is more robust than most slaves are in this regard. My PLC is communicating with SCADA using Modbus RTU through CM PtP module.Now I have a problem with the Modbus communication. Currently I am using S7-400H PLC, with ET200SP.

Problem communicating with modbus poll slave drivers#

Most serial port drivers today should not have a problem achieving this as long as the entire message is passed to the serial port driver in one call. Dear all,I have a question about Modbus Slave Communication. However, the WattNode is more tolerant and allows a gap between bytes of nearly the minimum silent interval. To strictly conform to the standard, the maximum time between sending any two successive bytes that belong to the same message should not exceed 1.5 character times (i.e. Backwards installation will not damage the line drivers, but communications will never work.Īfter swapping A/B lines, the miracle occur!!!! I can use modbus poll to get the data.īut when I perform other rtu 485 communication ,it's usually A1 to + ,B1 to -.With the Modbus RTU protocol, the start of a message begins with the first byte sent after a minimum silent interval (i.e.

Swapping the A/B lines on one end fixes it. If a Receive LED blinks, then the A/B wires are probably not crossed, but a common issue with RS-485 is that the A/B lines are labeled the opposite by different vendors. Look for a non-zero value because lots of slave devices zero out unused register so you might get a zero reply even though the data is from an address offset by one, and the real data is not zero. Slave devices include Wago, AEG/Modicon 984 and Quantum FIELDBUS COUPLERs, GE Fanuc Series-6, Series-5, Series-90, and many others. There are generally fewer things to set up or to go wrong with the generic masters, so it's easier to get the comm up and running.ĭoing so can also tell you whether the addressing Modpoll uses is offset by one, where address 0032 = (4)0033 Advantech WebAccess SCADA Node provides a Modbus master interface using Modbus RTU protocol implemented over TCP/IP for communicating with Modbus slave devices.

Problem communicating with modbus poll slave Pc#

Since you already have the Modpoll 3rd party PC master, you might consider reading some non-zero data from the slave device so that you can observe whatever feedback (blinking LEDs) the RS-485 port has for the slave device and gain the confidence that the slave does indeed talk Modbus. I am struggled in this stage for a long time.Īlso, can the s7-1200 communicate with the modbus device by 8n2?

I tried the modbus_slave and this remain in status 8280.Īlso,I used the mb_slave and status is 16#0000,only bad_CRC_COUNT is accumulated. Write small logic, while getting error bit of Modbus Slave block move the status in some other memory location.

Problem communicating with modbus poll slave software#

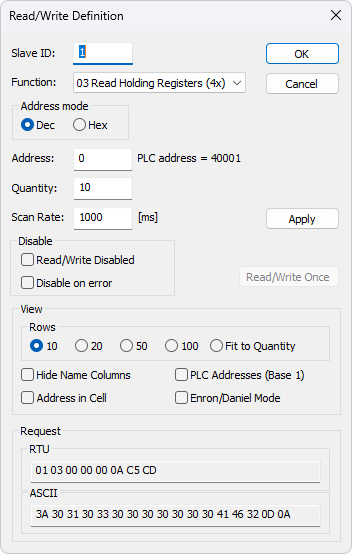

use Modscan software for testing.( Modbus Master) I tried to use modbus poll(third party software) through rs485/rs232 converter to read data by usingįunction 03(read holding register), but still fail and the modbus poll said write error:break condition. I used s7-1200 as a master can recevie data from different device.īut I used S7-1200 as a slave by using mb_comm_load and mb_slave and only receive bad_crc. I am using CPU1214C, DC/DC/RLY, firmware 4.1. I have a problem with the Modbus communication of a fire system, I use the Modbus Poll software for previous tests and everything works excellent.

Problem communicating with modbus poll slave code#

Post the outcome of status code here ,so expert can suggest you necessary changes. Move the MB Master/Slave status in other memory location while error bit is high. Write small logic to get status information. 04 SERVER FAILURE: the server failed during the execution. You can find so many modbus rtu sample application on Siemens support or forum. MODBUS ASCII/RTU is a master-slave communication protocol, able to support up to 247 slaves.

Which PLC version? Which software version? Is it MB Master or MB slave? Sorry but half information can get only half solution.

0 kommentar(er)

0 kommentar(er)